The manufacturing industry often interweaves multiple sectors and raw materials, creating a labyrinthine network of dependencies. A significant intersection exists between stearic acid, a fatty acid from animal or vegetable fats, and the global rubber industry. This relationship is profound, with stearic acid playing a vital role in the manufacture of various rubber-based products.

Stearic acid, with its unique chemical properties, contributes greatly to the rubber manufacturing process. It serves multiple purposes, including an activation agent for accelerators, a dispersing agent for fillers, and a binder or thickener. Plays a pivotal role in the industry as manufacturers use it in rubber vulcanization, a chemical process that hardens rubber.

As an activation agent, Enables a more efficient interaction between sulfur and rubber accelerators. This interaction significantly reduces the time and temperature required for vulcanization, increasing the production efficiency of rubber products.

In addition to accelerating the vulcanization process, stearic acid acts as an excellent dispersing agent for fillers. Fillers like carbon black or silica are crucial in enhancing the mechanical properties of rubber. However, their dispersion within the rubber matrix can be challenging. Stearic acid assists by enveloping these particles, preventing their agglomeration and ensuring a more uniform distribution, which leads to improved product consistency and quality.

Stearic acid also improves the processability of rubber compounds. Its lubricating properties help reduce friction during the processing, making the compounds easier to work with and extending the lifespan of processing equipment.

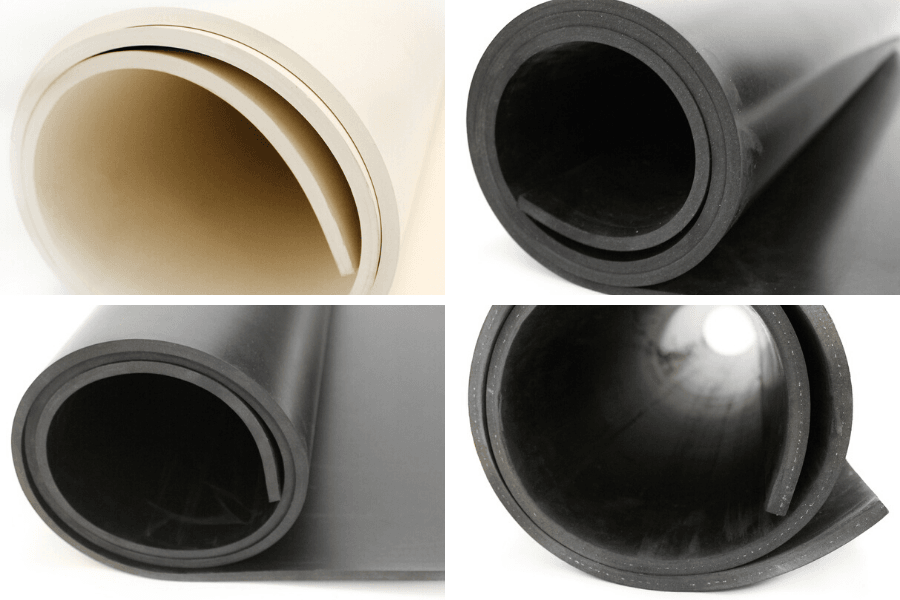

Moreover, it is critical in rubber vulcanization. In vulcanization, manufacturers heat rubber with sulfur to enhance its strength, elasticity, and durability. It enhances the vulcanization process by facilitating the reaction between rubber and sulfur. The result is a more durable rubber that can withstand high stress and environmental conditions, essential for products like automobile tires, industrial belts, and gaskets.

The rubber industry greatly values stearic acid due to its paramount importance. Its various roles ensure efficient production processes, improved product quality, and enhanced durability of rubber products. In an industry where performance, longevity, and reliability are paramount, stearic acid is an invaluable asset.

It’s also worth mentioning that is relatively safe to handle, non-toxic, and biodegradable, making it an environmentally friendly option. As industries worldwide face increasing encouragement or even mandates to minimize their environmental impact, this factor gains heightened importance.

In conclusion, the intersection of stearic acid and the rubber industry is a perfect example of how chemical compounds can dramatically influence manufacturing processes. As a crucial component in the rubber industry, it plays a key role in accelerating and enhancing production, improving the final product’s quality and durability. As the demand for high-performance rubber products continues to grow, so will the reliance on this versatile fatty acid. The relationship between stearic acid and the rubber industry exemplifies the intricate, yet often overlooked, connections that exist within the global manufacturing sector.