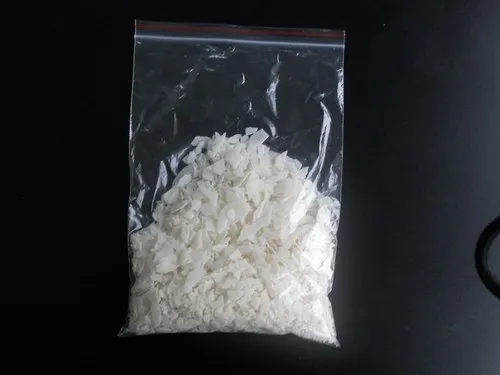

Polyethylene Wax (PE Wax), a derivative of ethylene polymer. It is a white, solid material that plays a key role in numerous industries due to its unique properties. PE Wax is known for its high melting point, low molecular weight, and excellent hardness. This article delves deeper into the specific role and critical importance of PE Wax within the realm of Polyvinyl Chloride (PVC) applications. And providing an in-depth understanding of how this versatile material helps shape the PVC industry.

Understanding Polyethylene Wax

Polyethylene Wax is a low molecular weight polyethylene polymer that arises from the process of polymerization of ethylene. This process yields a wax-like material that boasts a high melting point, hardness, and superior heat stability. PE Wax is available in a multitude of forms – from micronized wax to emulsions and prills – each suited to different applications.

PE Wax is characterized by its excellent lubrication properties. And due to its chemical inertness, it doesn’t interact with other substances easily. This characteristic makes it a fantastic choice as an additive in numerous applications, ranging from the plastic industry to cosmetics.

Polyethylene Wax in PVC Manufacturing

The manufacturing of PVC, a versatile plastic used in a multitude of products, represents one of the key areas where PE Wax is extensively utilized. PVC is inherently a rigid and brittle material; to increase its flexibility and adaptability for a wider range of applications, specific substances known as plasticizers are added.

However, the processing of PVC isn’t straightforward. PVC presents numerous challenges during its processing, especially during extrusion and injection molding processes. Due to its high viscosity and propensity to stick to the metal surfaces of machinery.

PE Wax, with its lubricating properties, comes to the rescue in these scenarios. When added to the PVC mixture during the manufacturing process, PE Wax helps to increase the plastic’s fluidity. Preventing it from adhering to the machinery and facilitating smoother molding and extrusion processes. This happens because the PE Wax coats the PVC particles, reducing friction between the particles themselves, and the metal surfaces of the equipment.

Notably, PE Wax also functions as a release agent in PVC. This means that it helps the final product to be released from the mold more easily. Reducing the risk of defects and improving the overall efficiency of the production process.

The Impact of PE Wax on PVC Products

Beyond facilitating the manufacturing process, PE Wax significantly influences the quality of the final PVC product. One of the most notable effects is that it aids in achieving a smooth, glossy finish on the PVC surface, greatly enhancing the product’s aesthetic appeal. This is particularly important for PVC flooring and other decorative PVC products where appearance plays a crucial role.

Another critical area where PE Wax proves beneficial is in PVC cables and wires. PE Wax aids in enhancing the insulation properties of these items. PVC by itself offers excellent electrical insulation properties.

Environmental Considerations

While PE Wax undoubtedly provides significant benefits in PVC production, it’s important to consider its environmental implications. PE Wax is a by-product of petroleum, a non-renewable resource. As the global movement towards sustainability gains traction, there’s increasing interest in finding bio-based and more sustainable alternatives to traditional PE Wax. As a result, researchers are exploring innovative ways to create bio-based PE Wax, hoping to reduce the environmental footprint of industries. Like the PVC industry, that use it extensively.

Conclusion

Polyethylene Wax plays an integral role in PVC applications. Not just contributing to the efficiency of the production process but also enhancing the final product’s performance. As the global PVC market continues to grow, so too does the demand for PE Wax. The future is likely to witness an increasing focus on the intersection of performance and sustainability in the use of these materials, with the development of bio-based alternatives being a promising step in this direction. As this unfolds, the role and application of PE Wax in the PVC industry are set to become more crucial than ever.