Aluminium stearate, a salt of stearic acid, is a material often relegated to the shadows of more well-known compounds. However, its diverse range of applications makes it indispensable in several industrial sectors, from the production of cosmetics and pharmaceuticals to its use in paints and construction materials. This article delves into the multifaceted world of aluminium stearate, highlighting its functions, benefits, and applications across various industries.

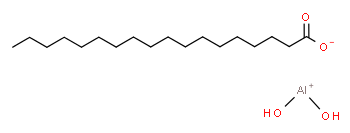

Chemical Composition and Properties

Before diving into its myriad applications, it’s crucial to understand the basic composition and properties of aluminium stearate. It consists of a metallic aluminium ion bonded to stearate ions. It is often a soft, fine, light powder with water repellent properties. Its hydrophobic nature, ability to form gels, and function as a stabilizing agent are some of the key properties that make it so versatile.

Cosmetics and Personal Care Industry

Emulsifiers

Aluminum stearate is widely used as an emulsifying agent in the formulation of creams and lotions. Its ability to stabilize oil-in-water and water-in-oil emulsions makes it highly valuable.

Thickening Agents

Manufacturers also use aluminum stearate as a thickening agent in the production of various cosmetic products like eyeliners and mascara, providing smooth application and long-lasting effects.

Pharmaceuticals

Tablet Manufacturing

In the pharmaceutical industry, manufacturers often use aluminum stearate as a lubricant in tablet production. It ensures that the tablet does not stick to the machinery during the compression process, thus ensuring smooth production operations.

Water Repellent Coating

Its water-repellent properties make it suitable for coating certain types of medication to ensure they are moisture-resistant, thereby prolonging their shelf-life.

Paints and Coatings

Anti-caking Agent

Aluminum stearate prevents caking in powdered pigments, which maintains the integrity of the colors and makes them easier to mix.

Gelling Agent

It acts as a gelling agent in certain oil-based paints, improving their texture and making them easier to apply.

Rubber and Plastics

Heat Stabilizer

In the plastics industry, aluminium stearate serves as a heat stabilizer for PVC, contributing to durability and longevity of the final product.

Release Agent

The use of aluminum stearate as a release agent in rubber production ensures easy removal of the finished product from molds, thereby minimizing production times and costs.

Construction and Cement

Water Repellency

Its water-repellent properties make it ideal for use in concrete and other construction materials to enhance resistance against moisture, increasing the lifespan of structures.

Setting Agent

Also used as a setting agent in plaster, making the application smoother and aiding in a faster drying process.

Food Industry

Regulatory agencies sometimes permit the use of aluminum stearate as an anti-caking agent in certain dry mixes under strict conditions.

Environmental Concerns and Future Directions

While aluminium stearate has proven to be highly functional, there are growing environmental and health concerns regarding its use. Researchers are investigating alternative, eco-friendly options that offer the same benefits but are biodegradable and less toxic.

Conclusion

From the pharmaceutical world to the realm of personal care, and from the rigors of industrial use to the specificity of food preparation, aluminium stearate serves multiple purposes that make it an invaluable component across industries. As we move towards a future focused on sustainability, it will be intriguing to see how aluminium stearate evolves, both in its traditional applications and new, innovative uses. Regardless, its diverse functionalities ensure it will remain a key player in various manufacturing processes for years to come.