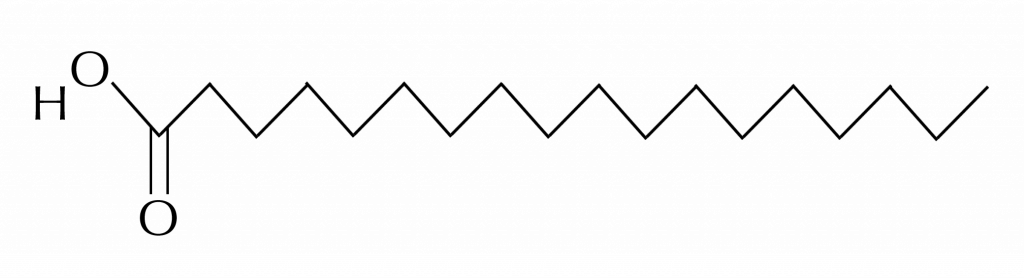

Stearic acid, also known as octadecanoic acid, is a saturated fatty acid primarily derived from animal fats, palm oil, and soybeans. In the rubber industry, stearic acid has held a position of prominence for many years, demonstrating a range of functionalities that are central to rubber processing, vulcanization, and the overall performance of rubber products.

1. Introduction: The Versatility of Stearic Acid

Before delving into the specific applications of stearic acid in the rubber industry, it’s important to note that this fatty acid is not exclusive to rubber manufacturing. It’s employed in a variety of industries, from the production of cosmetics and candles to plasticizers and food additives. This versatility is due to its unique properties, such as its plasticizing capabilities and its ability to stabilize mixtures.

2. Rubber Processing Aid (Application of Stearic Acid)

In rubber manufacturing, stearic acid acts as an invaluable processing aid. The incorporation of stearic acid:

- Improves Processability: Stearic acid serves as an internal lubricant, reducing the viscosity of the rubber compound and making it easier to process, mold, and shape.

- Enhances Dispersibility:. It ensures that fillers and other ingredients are uniformly dispersed throughout the rubber matrix. This results in a more consistent product with fewer defects.

3. Vulcanization and Activation (Application of Stearic Acid)

Vulcanization is a chemical process that transforms rubber from its original, plastic and sticky form into a more durable, elastic material. To achieve this, sulfur is typically added to the rubber, but the process requires accelerators and activators for optimal effectiveness.

- Accelerator Activator: Stearic acid plays an instrumental role as an activator for accelerators like zinc oxide. In this capacity, stearic acid enhances the efficiency of vulcanization, speeding up the cross-linking process.

- Scorch Safety: It also helps to increase ‘scorch safety’ – the time before unwanted premature vulcanization starts to occur during processing.

4. Improved Properties of the Final Product

Rubber products treated with stearic acid often demonstrate enhanced properties:

- Flexibility and Resilience: Stearic acid increases the flexibility and resilience of rubber, making it more resistant to wear and tear.

- Improved Aging Characteristics: It can reduce the rate at which rubber deteriorates over time, ensuring a longer product lifespan.

5. Cost-Effective

Given the efficacy of stearic acid in rubber production, it’s also a cost-effective ingredient. By improving processability and product quality, manufacturers can reduce waste and inefficiencies in the production line.

6. Environmental and Ethical Concerns

With the increasing demand for sustainable and ethical manufacturing, the rubber industry, like many others, is under scrutiny. Stearic acid derived from palm oil is of particular concern due to deforestation and habitat destruction associated with palm plantations.

However, it’s worth noting that there are sustainable sources of stearic acid. Some manufacturers have started to adopt sustainably sourced stearic acid to meet these concerns.

7. Conclusion

The importance of stearic acid’s diverse role in the rubber industry is immense. From facilitating processing to optimizing the vulcanization process and enhancing the end product’s properties, it remains a cornerstone ingredient. As the rubber industry continues to evolve, the use and sourcing of stearic acid will undoubtedly adjust to meet new challenges and demands.