Epoxidized soybean oil (ESO) has become an indispensable component in numerous industrial applications, with the wire and cable industry being one of its prominent consumers. As an eco-friendly, biodegradable, and renewable resource, ESO offers an attractive alternative to traditional petrochemical-based plasticizers. This article delves into the unique properties and advantages of ESO in the wire and cable industry.

Background on Epoxidized Soybean Oil

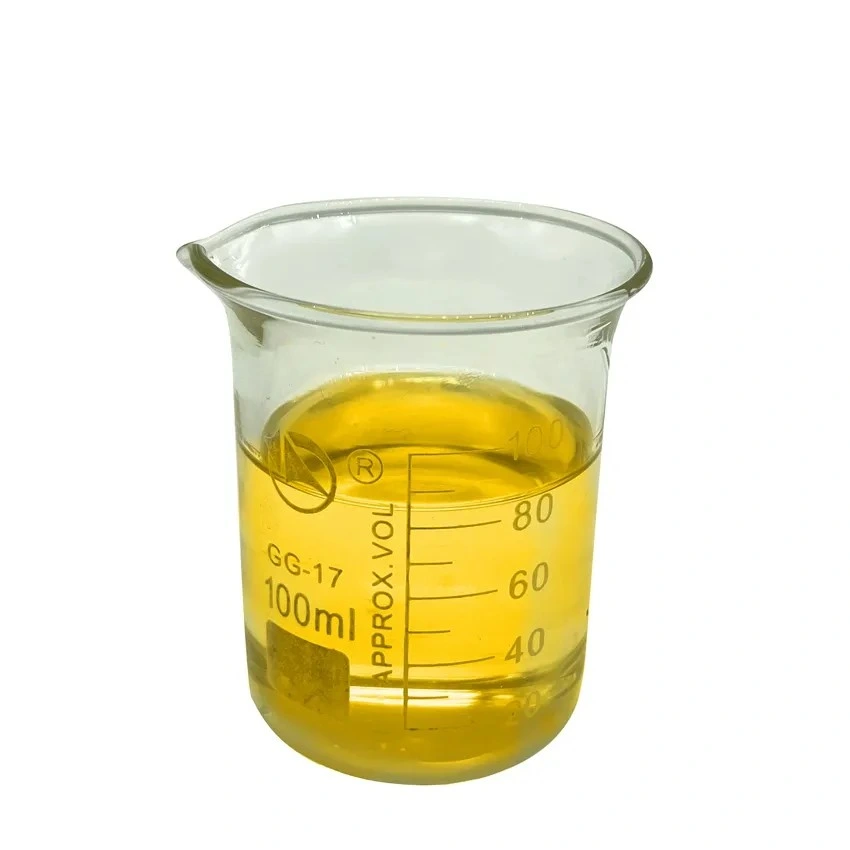

ESO is derived from the oxidation of soybean oil, transforming its unsaturated bonds into epoxide groups. This epoxidation not only endows the soybean oil with improved thermal and oxidative stability but also makes it a more effective and flexible plasticizer. Over the years, the push for sustainable solutions has encouraged industries to shift their preferences from phthalate plasticizers to more environmentally benign alternatives like ESO.

Properties and Advantages of ESO in Wire and Cable Applications (Role of Epoxidized Soybean Oil in Wire and Cable Industries)

- Thermal Stability:. During operations, wires and cables frequently encounter elevated temperatures. ESO’s improved thermal stability ensures that the cable’s plastic coating does not degrade rapidly, maintaining its insulative properties for longer periods.

- Low Volatility:. ESO exhibits low volatility compared to other plasticizers. This is crucial for wire and cable applications as it minimizes the loss of plasticizer over time, preserving the flexibility and mechanical properties of the cable.

- Bio-based and Renewable:. Manufacturers derive ESO from soybeans, which means it’s a renewable and sustainable resource. This helps industries meet environmental regulations and sustainability goals.

- Compatibility with Polymers:. Manufacturers have found that ESO is highly compatible with many polymers, notably PVC, frequently used for wire and cable insulation.

- Non-toxicity: ESO is non-phthalate based and lacks any potentially harmful additives, making it safer for both human and environmental health.

Applications in Wire and Cable Industries

- PVC Cable Insulation:. Polyvinyl chloride (PVC) remains one of the most commonly used materials for cable insulation. ESO acts as a secondary plasticizer in PVC, aiding in enhancing its flexibility and overall performance.

- Cable Sheathing:. Protecting the inner layers of a cable, the sheathing is vital for safeguarding against external factors. ESO contributes to the durability and flexibility of this outer layer.

- Cable Gels and Fillers:. When bundling cables together, manufacturers utilize epoxidized soybean oil in gels and fillers to bridge the spaces between individual cables. This prevents the cables from rubbing against each other and causing wear.

Environmental Impact and Sustainability

The increasing demand for green and sustainable materials has put ESO at the forefront of wire and cable industries. By substituting traditional petroleum-based plasticizers with ESO, industries can significantly reduce their carbon footprint. Additionally, ESO‘s biodegradability ensures minimal environmental contamination at the end of the cable’s lifecycle.

Challenges and Future Outlook

Epoxidized soybean oil (ESO) provides many advantages, but challenges still exist that need addressing. There’s a need for further research to enhance its properties and find cost-effective production methods.

The future outlook for ESO in the wire and cable industry is promising. Industries are increasingly turning to eco-friendly alternatives, driving up the projected demand for epoxidized soybean oil. Moreover, ongoing research may unlock even more applications for this versatile compound.

Conclusion (Role of Epoxidized Soybean Oil in Wire and Cable Industries)

The role of epoxidized soybean oil in the wire and cable industries is evolving and expanding. Its unique properties, combined with its sustainable nature, make it a frontrunner in the shift towards green and sustainable manufacturing practices. As the world continues to grapple with environmental challenges, materials like ESO will undoubtedly gain more prominence in various industrial applications.