In the contemporary world of sustainable innovations, Epoxidized Soybean Oil (ESBO) has emerged as a frontrunner in multiple applications. ESBO, derived from soybean oil through an epoxidation process, exhibits impressive properties, making it suitable for various applications. One sector that has particularly benefited from ESBO’s attributes is the medical industry. This article delves deep into the usage and applications of ESBO in medical products, shedding light on its growing relevance in today’s healthcare landscape.

1. What is Epoxidized Soybean Oil (ESBO)?

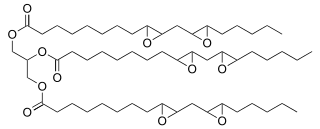

Epoxidized Soybean Oil is a non-toxic, clear to yellow liquid that is used as a plasticizer and stabilizer in plastics. It is the most readily available bio-based secondary plasticizer with over 90% content of unsaturated fatty acids.

2. Benefits of ESBO in Medical Products

a. Biocompatibility:

One of the prime concerns in medical applications is biocompatibility. ESBO, being derived from natural sources, is inherently biocompatible, minimizing the risk of adverse reactions when used in medical devices and products.

b. Plasticization Properties:

ESBO acts as an excellent plasticizer. In PVC (Polyvinyl Chloride) medical devices, such as IV bags, tubing, and catheters, ESBO helps in imparting flexibility, which is crucial for both patient comfort and device functionality.

c. Thermal and Photostability:

Medical products often undergo sterilization procedures that expose them to high temperatures or UV light. ESBO’s inherent stability ensures that the medical devices remain intact and functionally viable post-sterilization.

d. Non-Toxic Nature:

The non-toxic characteristic of ESBO is paramount in medical applications. It ensures that even if minute amounts leach into the body, they do not pose significant health risks.

3. Key Applications in the Medical Sector

a. Medical Tubing and Bags:

ESBO, when combined with PVC, provides the desired flexibility and softness, making it ideal for IV bags and various types of medical tubes.

b. Medical Gloves:

ESBO’s plasticizing property is also beneficial in manufacturing medical gloves that need to be flexible, durable, and safe for direct skin contact.

c. Catheters and Surgical Instruments:

Many catheters and some surgical instruments are made from PVC. ESBO ensures these instruments remain pliable, aiding in their function while ensuring patient safety.

d. Wound Care Products:

Due to its non-toxic nature, ESBO finds its place in certain wound care products, ensuring flexibility without compromising the healing process.

4. Environmental and Economic Benefits

a. Reduction in Phthalate Usage:

Traditionally, many medical products relied on phthalates as plasticizers. Given the potential health concerns associated with certain phthalates, ESBO provides a safer alternative.

b. Sustainable Sourcing:

Soybeans are a renewable resource, making ESBO an environmentally friendly option. By choosing ESBO-based medical products, manufacturers and consumers contribute to a more sustainable and greener future.

c. Cost-Efficiency:

Due to the abundant availability of soybeans and the scalability of the ESBO production process, it can be a cost-effective alternative to traditional plasticizers in the long run.

5. Conclusion

The transition towards sustainable solutions in every sector is not just a trend but a necessity. In the medical domain, patient safety remains paramount. ESBO bridges the gap between sustainability and safety. With its unique set of properties tailored for medical applications, coupled with its environmental benefits, Epoxidized Soybean Oil stands tall as a cornerstone in the evolution of medical products.